Ellex began as a defence industry spin-off in the ’80s, but has evolved to become a globally-recognised name among eye doctors, and a shining local example of advanced manufacturing success.

Manufacturing success

Ellex was innovating long before the term became a ubiquitous economic buzzword.

The SA-based company, which now also has two offices in the United States, was small and local when it launched in 1990.

Ellex CEO Tom Spurling

That year, Ellex established itself as a spin-off from Quentron Electronics – a scientific laser firm under the auspices of which Ellex’s core technology – lasers for opthamology – had been developed.

“Adelaide – because of the defence industry at Salisbury – really spawned some fundamental laser technology,” says Ellex CEO Tom Spurling.

“We had some fundamental laser physicists in the ’60s and ’70s here, that had the capability to understand lasers, and the original business is about lasers. Our founder Victor Previn is one of those guys.”

But the company has not been content to survive on one initial innovation. Basil Fermantzis – senior project manager of operations, who has been with the company for almost two decades – says Ellex’s breakthrough into the market was supported by a new way of thinking about medical lasers.

More than 90 per cent of Ellex’s products are sold offshore, but about 70 per cent of their staff are based in Australia, with the vast majority of those in South Australia.

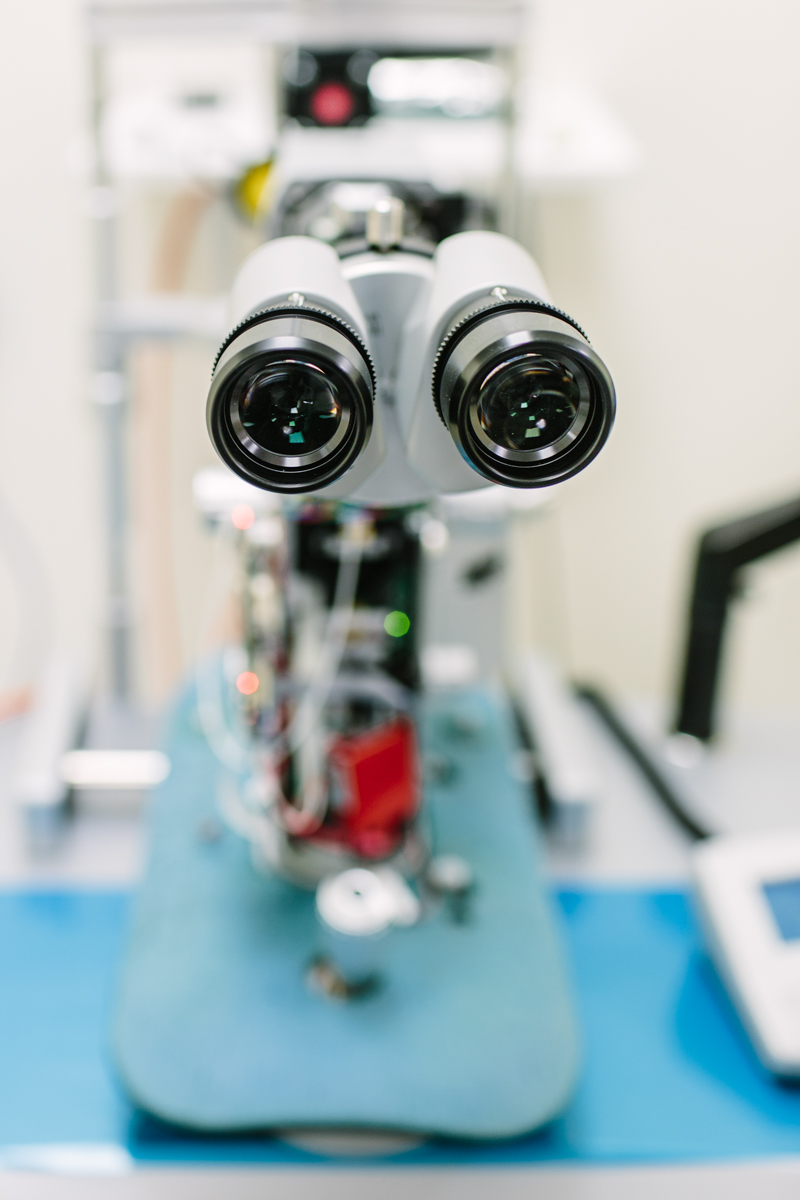

It’s not WALL-E. It is an assembly module of the – on average – 700 components used in an Ellex laser

“When they first entered the market, if you had a laser and it broke, it was out for a long time. You’d have to take it back to the factory and it was huge, it was bulky,” he says.

“What Victor designed was a laser that was modular. Which meant a service guy came with a suitcase with half a dozen modules, and then they’d find one piece is broken, replace it – and then within one hour or two hours, it’s back up and running. Everyone loved it.”

From there, a history of constant evolution has seen Ellex grow from manufacturing two products in its Halifax Street location throughout the ’90s, to moving into another city facility in Gilbert Street in 2001, where the product range more than quintupled and the firm floated on the Australian Stock Exchange.

This year, Ellex has relocated to a new headquarters in Mawson Lakes to accommodate ongoing growth in its manufacture of devices to treat glaucoma, diabetic eye disease, secondary cataract, age-related macular degeneration, and vitreous opacities. Increasing demand is coming particularly from China, but certain products are also attracting huge interest in America.

Tom says maintaining this sort of constant growth requires an acute understanding of the market.

“We have to be outward looking, and make sure that we understand the changes in the global market,” he says. “What’s going on? What do doctors need? What is happening?

“So we have to do a lot of travel. We make decisions here, but we don’t gather much information here.

No lab is complete without a collection of white Crocs

“And then you have to turn that information – using engineers from around here – into something that can be designed, built, consistently delivered, meets regulatory approval requirements, and all those sorts of things.”

Responding to market needs and a smart global marketing presence has helped Ellex become a name that is recognised internationally in opthamology, but the quality of output has also been essential in this process.

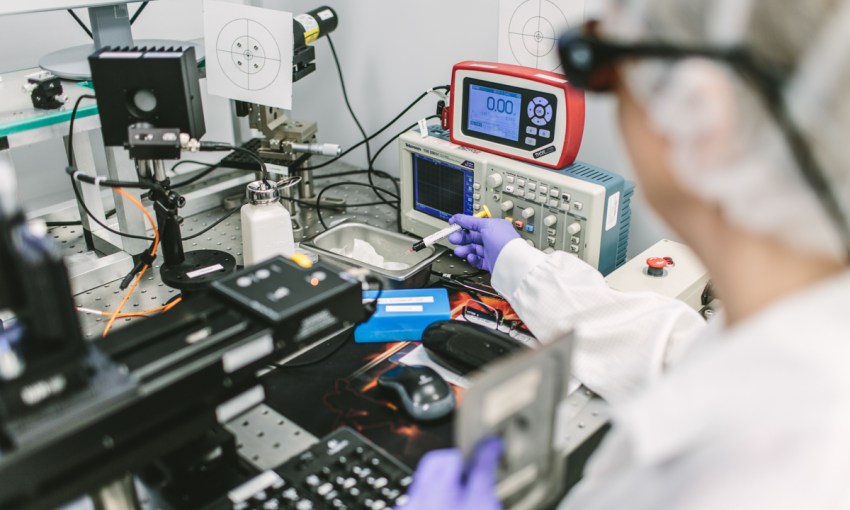

Many of Ellex’s products are hand-manufactured, and Basil says the skill of the workforce is at the business’ core.

“What makes it good is the actual people who work here – that’s what makes good lasers,” he says.

“It’s a very diverse team, we have people from everywhere, and I think that contributes to our product – that diverse knowledge. Our product is basically better designed and better made than any other products.”

The company is proof that Adelaide – despite its distance from the rest of the world, and a rapidly disappearing manufacturing culture – can still make things that are bought around the globe.

All that’s required is some world-leading thinking, and some world-leading skills.