On the ninth floor of the Polites Building at the corner of King William and Pirie Streets, a little watch workshop is quietly building the capacity to manufacture a watch entirely of their own imagination.

R. McMahon Watchmakers inches closer to manufacturing their first watch in Adelaide

In the midst of the Information Age, Adelaide watchmakers R. McMahon Watchmakers have experienced nothing but growth since setting up shop specialising in analogue vintage watch repair, restoration and sales.

Horology is a finicky business – part craft, part micro manufacturing. It’s a niche industry worth billions of dollars worldwide.

And while tech companies race to attach yet more data retrieval devices to your person, Rolex can afford to attach another famous and influential face to its already impressive suite of endorsers.

On the ninth floor of the Polites building at the corner of King William and Pirie streets in Adelaide, CityMag couldn’t feel further away from the glamour and success of a brand like Rolex. However, it is here – in a small-but-growing business – that the real value of a brand like Rolex is revealed.

“You spend $15,000 on a Rolex and you’re getting more than $15,000 worth of watch,” says Richard McMahon, founder and company director of R. McMahon Watchmakers.

Founder of R. McMahon Watchmakers – Richard McMahon

“How?” is one question we have for Richard and, why? is another. It strikes CityMag as odd that a business in the 21st Century could or would offer their customer more value than they’re asking for via their recommended retail price. How can Rolex, a company that has Roger Federer on speed dial, give more watch than what we’re buying?

“To give you an example,” says Richard leaning forward on his workshop stool. “I had a $50,000 solid gold watch come in – I won’t say what company it’s from, but it was a very big one. Yeah, $50,000 watch, and when I opened up the back of it, I found it had a $150 – really poor quality – Swiss movement in it.

“The part had broken and the company wouldn’t service the watch, they’d just do a movement swap and that’s it until they served out whatever warranty it came with.

“But that Rolex, the Rolex worth $15,000 is going to be around in 100 years’ time. They’re amazing value for money,” says Richard.

Richard started as an apprentice watchmaker in 1989. He’s seen the world change, the incredible and miraculous feats of technology arrive and evolve and threaten his industry, only to discover his profession is worth more now than when he started.

“The business started out in 2015 with 40 square metres,” says Richard.

“18 months ago, we added another 25 square metres. Six months ago, I added another – approximately – 15 square metres. So, I’m filling up this space with more machinery and drawers full of spare parts,” he says. Business is good for an outfit willing to fix things rather than throw them away and sell you a new one.

The view from R. McMahon Watchmakers’ workshop includes not one, but two clock towers

R. McMahon Watchmakers is a vintage watch repair and restoration specialist servicing clients from around the world. When you Google ‘Rolex Restoration’ – in Australia at least – you’re going to find R. McMahon Watchmakers.

But Richard’s success has been a long time coming. After his apprenticeship he did, what he calls, “six hard years” with a clock repairing and pocket watch restoration business in Sydney. There he learnt, “make what doesn’t exist anymore,” says Richard with the sort of understated poetry that makes a writer take notice.

From Sydney, Richard travelled to London and a job at Somlo Antiques in Piccadilly. There he helped the owners set up a more significant workshop for engineering parts and pieces for watches and clocks that could no longer be sourced from the original manufacturers.

But owning his own shop was always the dream and upon returning to Adelaide, after a short stint in

Sydney on the way back from London, Richard took out the lease that he’s steadily built on to this day.

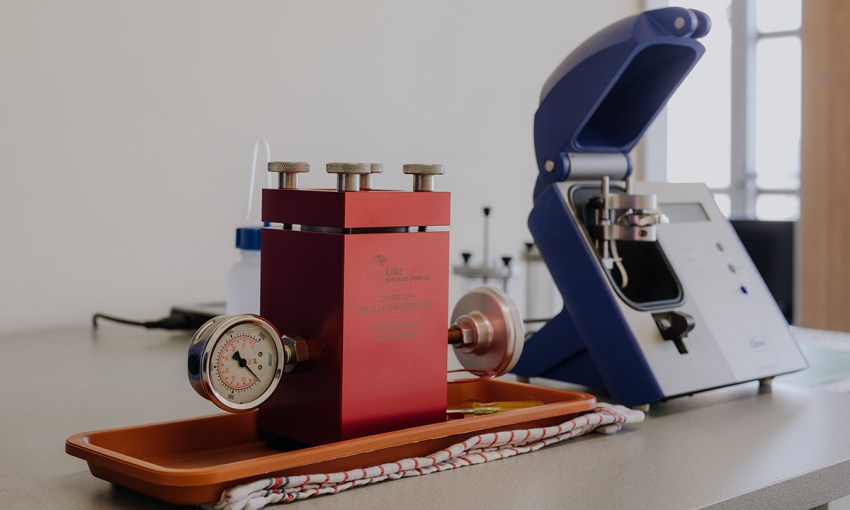

Before R. McMahon Watchmakers grew its floorplan though, it first had to grow its capacity. The workshop is filled with machines. Each machine is a variation on a theme, looks incredibly precise, and usually has a bit of German text down one side. We do a double take though when Richard points at his very own laser.

Again. Why?

“I’m actually finishing a job today for a client in Queensland who sent me a solid gold Rolex bracelet that was quite twisted and damaged,” says Richard.

“The client had been told by Rolex that there was no option to repair it, that it had to be replaced. He sent the bracelet down to me after searching ‘Rolex’ and ‘Restoration’ on the Internet. I just worked out a technique with the laser welding machine that meant instead of drilling in to fix the broken part, I was able to cut holes with the laser and insert gold into the holes, fill up the section where it was damaged and re-fill it with 18 carat, polish it and cut it back.

“For well under $1,000 we were able to restore the existing piece versus the $9,000 it was going to cost to replace what was otherwise a perfectly good bracelet,” says Richard.

It’s this commitment to innovation and creativity that has attracted two world-class watchmakers to Richard’s operation.

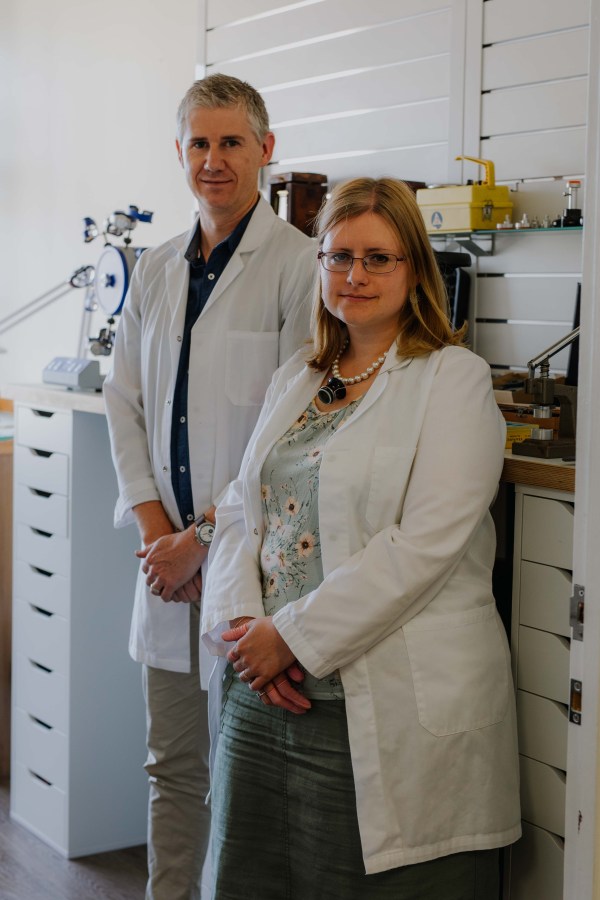

Watchmakers, Aaron Lawrence and Sophie Hunter

Aaron Lawrence is a watchmaker with 20 years’ experience and Sophie Hunter has just moved here from England, where she graduated from the British School of Watchmaking in 2015 and – more recently – completed a number of certificates working for the Swatch Group (Omega) as an Omega chronograph expert in London.

“Moving from London to Adelaide I didn’t think I’d be able to stay in watchmaking,” says Sophie. “But here I am.”

In contrast to Sophie, Aaron was most recently self-employed and has given that up to work for a company he sees as one of the best in the business.

“This would be the best workshop I’ve seen outside of Swatch,” says Aaron. “I’m fascinated by micro mechanics and there’s just so much to learn here.”

The team of three have a steady hum about them, when CityMag visits. With eyeglasses in, they barely look up when Richard introduces us.

For some time R. McMahon Watchmakers suffered from a crippling back-log of work, but now Richard says he’s able to spend more than 50 per cent of his time working on streamlining business systems, customer experience, and marketing his company’s services.

He’s also got time to quietly dream of the day, in the not too distant future, when he can commence work on his ultimate goal for R. McMahon Watchmakers – a wristwatch made entirely in his King William Street workshop.

Richard has already built two pocket watches from the ground up. However, the start date for his own wristwatch is still some time off yet.

“It’ll be at least a year until I can sink my teeth into building a custom watch from scratch for a client,” says Richard. “It’s something I really want to do, but I have to be able to do it to the level I want and be able to make money out of it.”

There are three or four clients – watch collectors – Richard has the names of, who have told him they want to be the first to own an R. McMahon timepiece. The project is on ice right now, while he completes the workshop and settles Sophie into the business, but the plan is definitely real.

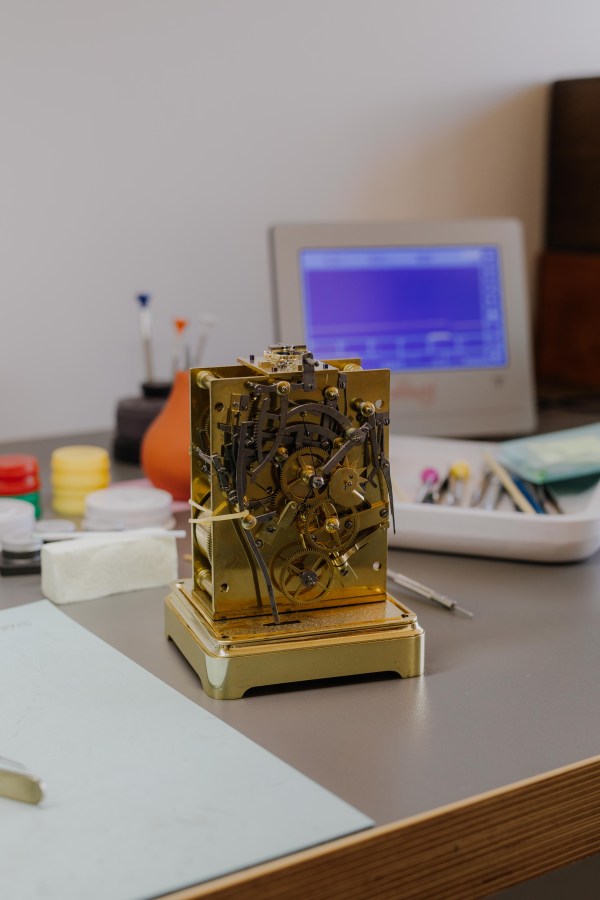

Precision instruments and details of the micro-manufacturing facility Richard is building at R. McMahon Watchmakers in Adelaide

Beyond Richard’s ambition, though, is his commitment to the industry and his profession. Building a watch from nothing is not about making a quick buck, about replacing components wholesale, and pushing up margins on a spreadsheet by reducing the cost (and quality) of your inputs.

If R. McMahon Watchmakers are going to make a watch, then it’s going to have to add something new, something innovative, that’s different, and complicated, and a joy to engineer.

“The first couple of watches will take a whole year to build,” says Richard after we press him for yet more details on his Adelaide-made watch project.

“The following we might be able to do four. The year after that, more,” says the watchmaker staring out the window towards a point in the future only he can see.

The beauty of horology we’ve discovered during the course of our conversation with Richard is that this industry and its professionals value time and money differently to other industries.

In the same way that Rolex derives its success by selling expensive watches that are worth more than they charge, Richard has a long-term vision for any watch he makes.

Far more important than successfully launching a new watch brand to the market is the belief that any product R. McMahon Watchmakers puts its name to will last well beyond launch and survive the only test that matters – the test of time.